In order to take control of your control panels, you first need to understand all of the aspects of the creation, design, and standards that are required. Industrial control panels (ICPs) are defined by the National Electrical Code (NEC) Section 409.2 as: an assembly of two or more power circuit components, control circuit components, or any combination of power and control circuit components.

When designing an ICP, the panel builder goes through various steps to ensure that their design functions most efficiently for the end user, is compact and most importantly complies with the NEC. They will start by laying out the panel and identifying feeder and branch circuits.

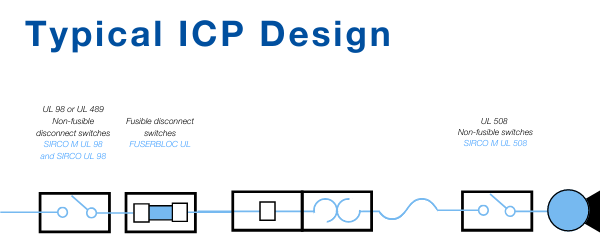

A branch circuit is everything downstream of the last over-current protective device (fuse or circuit breaker) that is protecting a single load’s conductors and components (typically a motor, lights or a transformer). Everything about the branch circuit is considered a feeder circuit. The importance of this is that the NEC defines what types of components can be employed in feeder or branch circuits.

The NEC defines that UL 98 or UL 489 approved products be employed in feeder circuits as their construction complies with service entrance spacing requirements and the products are marked accordingly. These products also must pass more rigorous testing requirements such as higher short circuit current withstands as feeder circuits may see more demanding requirements. UL 508 products cannot be used in the feeder circuit.

On the other hand, branch circuits see less demanding requirements and lower short circuit current withstands so the NEC states that branch circuits may employ UL98, UL 489 or UL 508 components. As UL 508 components do not meet service entrance spacing requirements and do not require high short circuit withstand ratings, they are physically smaller and consequently less expensive. UL 508 switches can be considered manual motor controllers and are marked as suitable as motor disconnect. Thus the UL 508 components are typically selected for use in branch circuits to provide more cost effective and compact solutions.

Socomec offers UL 98 non-fused disconnect switches and UL 98 or UL 489 fused disconnect switches as solutions for feeder circuits ranging from 30A to 1200A.

SIRCO M (UL 98)….our most popular choice for compact non-fused solutions from 30-100A

SIRCO (UL 98)….rugged, robust and reliable non-fused solutions for 100-1200A

Fuserbloc (UL 489)….compact fused solutions for 30A & 60A with 100kA SCCR

Fuserbloc (UL98)…..heavy duty fused solutions for 30A-800A with 200kA SCCR

For branch circuits any of the above solutions can be utilized, but most often we see customers selecting the UL 508 non-fused disconnect solutions for loads less than or equal to 100A.

SIRCO M (UL 508)….most compact, cost effect non-fused solutions from 30A to 100A

In addition to these disconnect switches, Socomec also offers other UL approved components that can be utilized in ICPs to complete customer’s application requirements and solutions including.

RM Series Class CC fuse holders (UL 4248-4)

RM Series fuse holders for 10×38, 14×51 & 22×58 mm fuses (UL component recognized 4248-1)

Power distribution blocks (UL 1953 and UL component recognized 1059)

COMO CS manual cam changeover switches (UL 60947-4-1)

SIRCOVER changeover switches (UL 98)

Insulated flexible copper bars (UL 67 / UL 891 recognized components)

Busbar supports (UL 94 V0)

DIRIS A, DIRIS B single point power metering & monitoring (UL 61010-1)

DIRIS Digiware multipoint power metering & monitoring (UL 61010-1)

If you have additional questions or want more information on any of Socomec’s solutions to incorporate into ICPs, please contact Socomec Inc. at info.us@socomec.com for further details.