Current Sensors

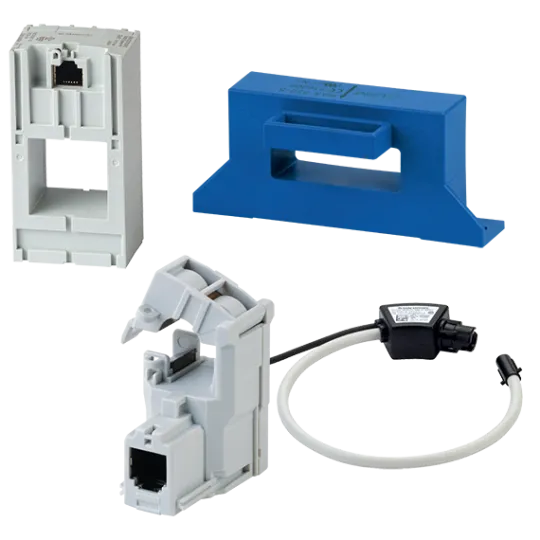

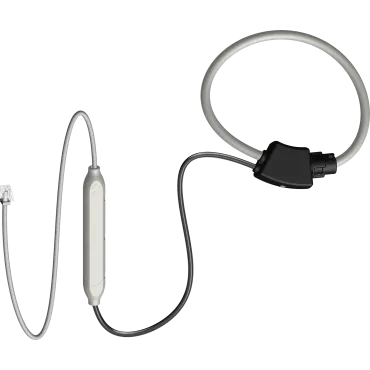

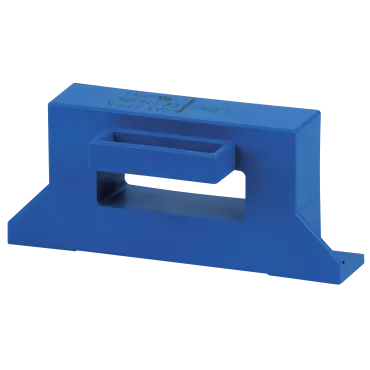

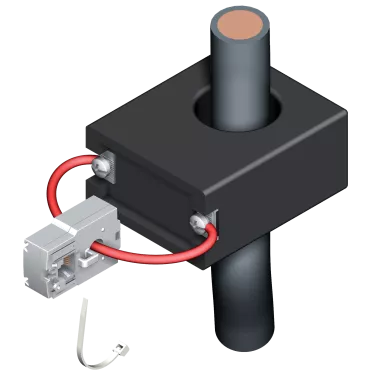

Solid-core sensors are typically best suited for new installations, while split-core and Rogowski sensors, thanks to their open-ended design are ideal for existing installations because they do not require to disconnect the distribution cables from protective devices. Rogowski sensors, unlike conventional rigid sensors are ideal for busbars, cable bundles, tight spaces and high current applications.

By manufacturing both power meters and current sensors, Socomec can master the accuracy of the complete measurement chain, for accurate and reliable measurements under all conditions.